We believe that using the most modern equipment available and the most advanced engineering and production techniques will result in higher quality parts economically produced for our customers. The manufacturing division spearheads our integration of sheet metal fabrication, welding, machining, and assembly processes for the creation of high-quality products, which satisfy all customer requirements; quality, low cost, and quick response time. As a full-service company, J.K Engineering Works offers total start to finish capabilities, including sheet metal, machining, welding fabrication and metal finishing.

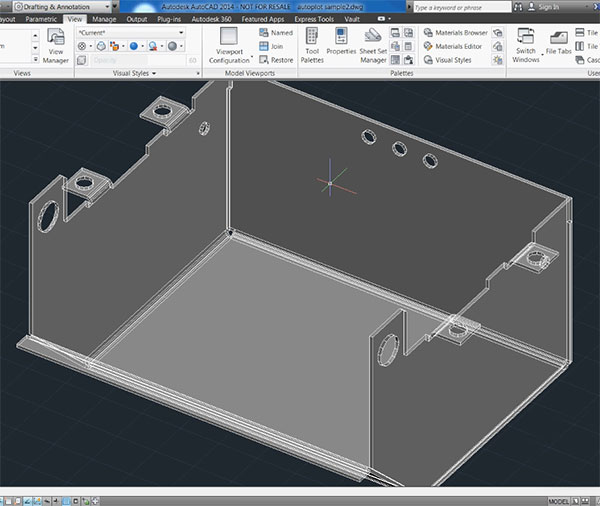

Our clients provide us either 3D design of product or 2D drawings of products. In either case design & prototype is involved. We processed through software to convert the 3D product in flat development for laser cutting. The Design of complex bending parts poses a challenge to every designer. The 2D drawings of the product also involve development of the flat view by providing for standard bend allowances. We have an expert design department which works in close association with the engineering department.

Types of Metal Shearing:

Aluminum, Carbon Steel, High-Alloy Steel, Iron, Nickel-Based Alloys, Sheet Metal, Stainless Steel, Steel, and Structural Steel.

We do Precision Sheet metal bending with servo driven Hydraulic press brake made by HINDUSTAN HYDRAULICS. Advantages of our Press Brake Bending include,